D5 Coolant Monitor for Energy Saving

D5 Coolant Monitor for Energy Saving

Brand: pFlow

Model : D5

Place of Origin: Shenzhen, China

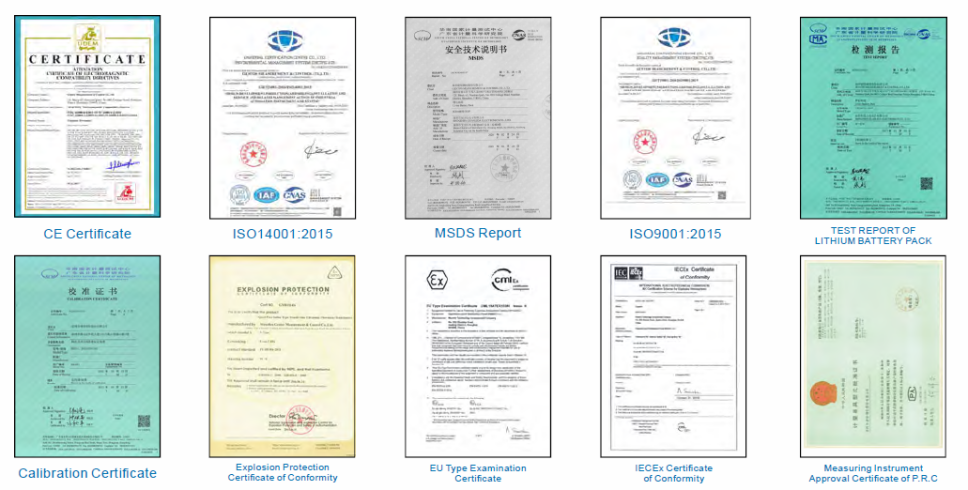

Certification: ISO9001,ISO14001, CE

Payment & Shipping Terms

Delivery Time: 2~4 days

Minimum Order Quantity: 1

Packaging Details: Carton Packing

Payment Terms: 100% T/T /Cash

Accuracy:±2.0% of RD Output: 4~20mA,max load 500Ω |

Pipe size: DN50~DN150 Flow velocity Range: 0.03m/s ~5.0m/s |

Pipe Material: Stainless Steel Display: 1.54"LCD colorful screen, Resolution 240*240 |

Medium:Deionized Water, Ethylene Glycol-Water Mixture, Propylene Glycol-Water Mixture, Oil-Based Coolant, Fluorocarbon Fluid |

PRODUCT INTRODUCTION

D5 Coolant Monitor for Energy Saving

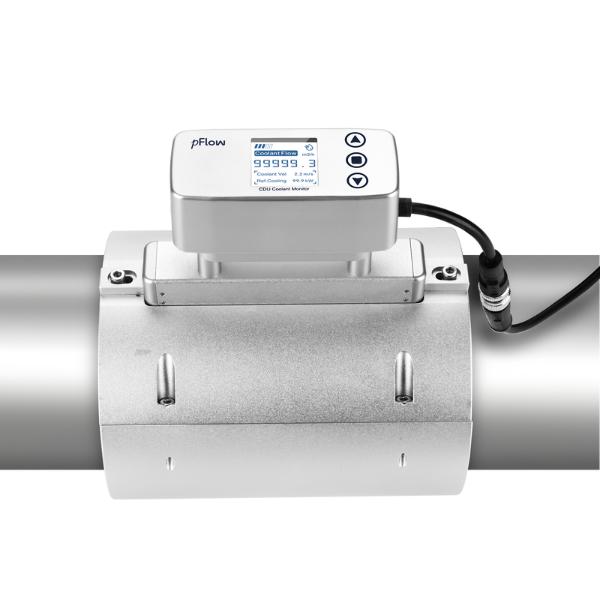

D5 CDU Coolant Monitor is mounted on the cold-source side of liquid-cooling loops to track flow in DN50–DN150 stainless lines. By feeding real-time m³/h data via RS485 MODBUS to pumps, valves and the building BMS, it closes the control loop so chilled coolant is delivered only where and when required.

This eliminates over-pumping, cuts bypass losses and lowers PUE; operators can instantly spot blocked CDUs or under-performing racks and rebalance flow instead of raising global supply temperature. Continuous, non-invasive monitoring also prevents thermal runaway that would otherwise force emergency chiller staging, delivering measurable energy savings in data centers and semiconductor fabs.

SPECIFICATIONS

Performance Index | |

Flow Velocity Range | 0.03m/s ~5.0m/s |

Accuracy | ±2.0% of RD |

Repeatability | 0.4% |

Pipe Size | DN50,DN65,DN80,DN100,DN125,DN150 |

Medium | Deionized Water, Ethylene Glycol-Water Mixture, Propylene Glycol-Water Mixture, Oil-Based Coolant, Fluorocarbon Fluid |

Pipe Material | Stainless Steel |

Function Index | |

Communication Interface | RS485, Support MODBUS Protocol |

Output | 4~20mA,max load 500Ω |

Power Supply | 10~36VDC/500mA |

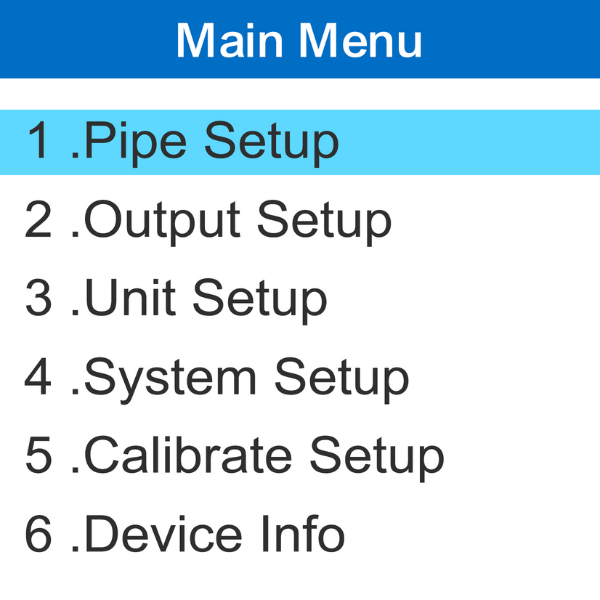

Keyboard | 3 Touch Keys |

Display Screen | 1.54"LCD colorful screen, Resolution 240*240. |

Temperature | Transmitter:-10℃~50℃ |

Humidity | 20~99% relative humidity, no condensation |

IP | IP65 |

Physical Characteristics | |

Housing Material | PC engineering plastic |

Pipe Clamp Material | Aluminum alloy |

Transmitter | Integrated |

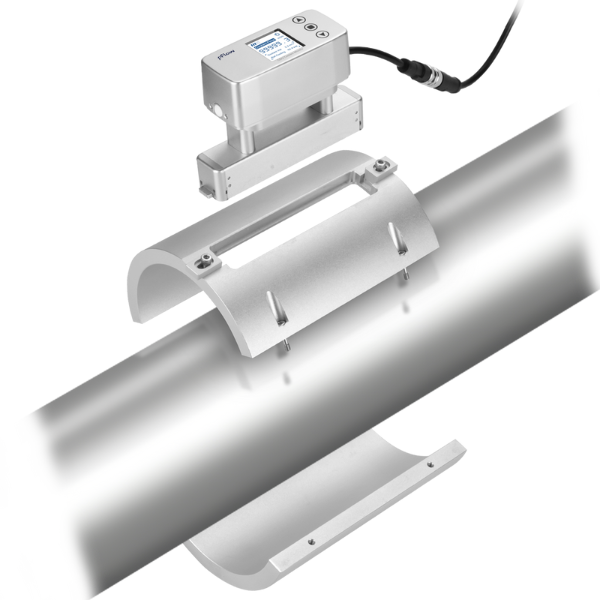

Transducer | Clamp-On |

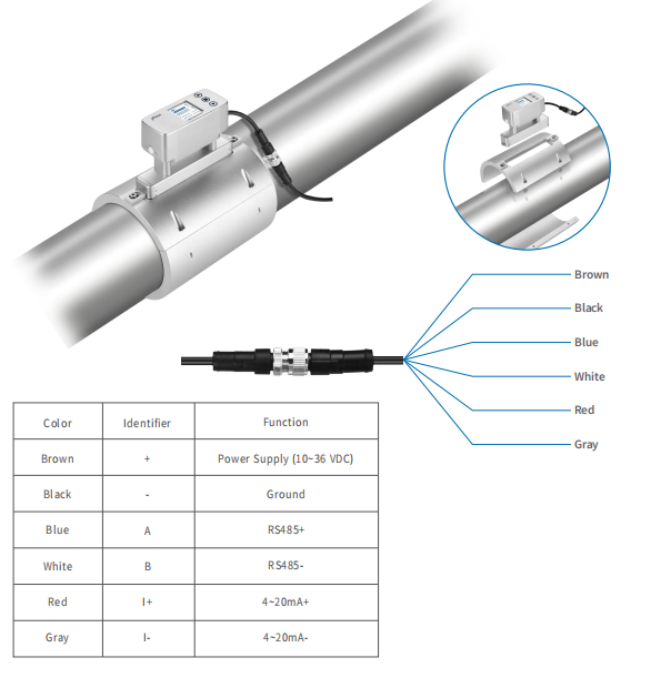

cable | ф5 black six-coreshielded cable with M12 A-Code connectors, standard length: 2m |

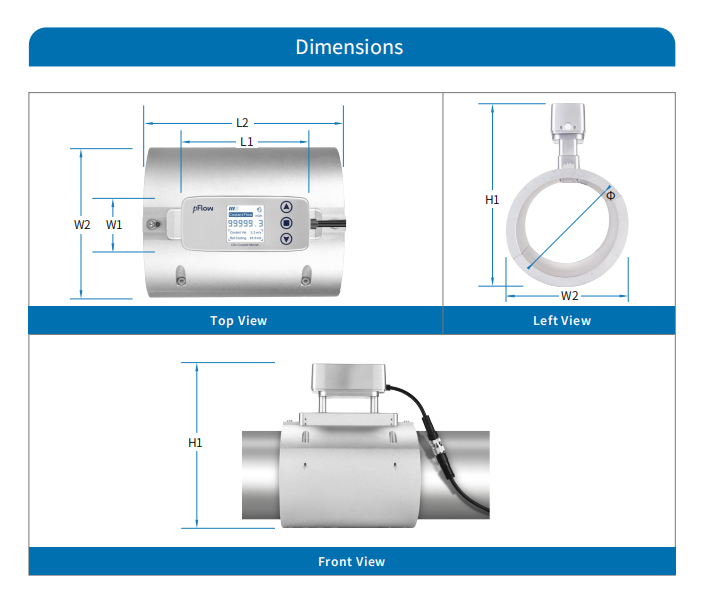

Pipe Dimension Comparison Table Unit:mm | ||||||

Nominal Inner | W1 | W2 | L1 | L2 | H1 | Ø |

DN50 | 42 | 89 | 96 | 153 | 163 | 67 |

DN65 | 42 | 102 | 96 | 153 | 176 | 80 |

DN80 | 42 | 113 | 96 | 153 | 187 | 91 |

DN100 | 42 | 138 | 96 | 165 | 214 | 116 |

DN125 | 42 | 160 | 96 | 180 | 237 | 140 |

DN150 | 42 | 190 | 96 | 180 | 267 | 190 |

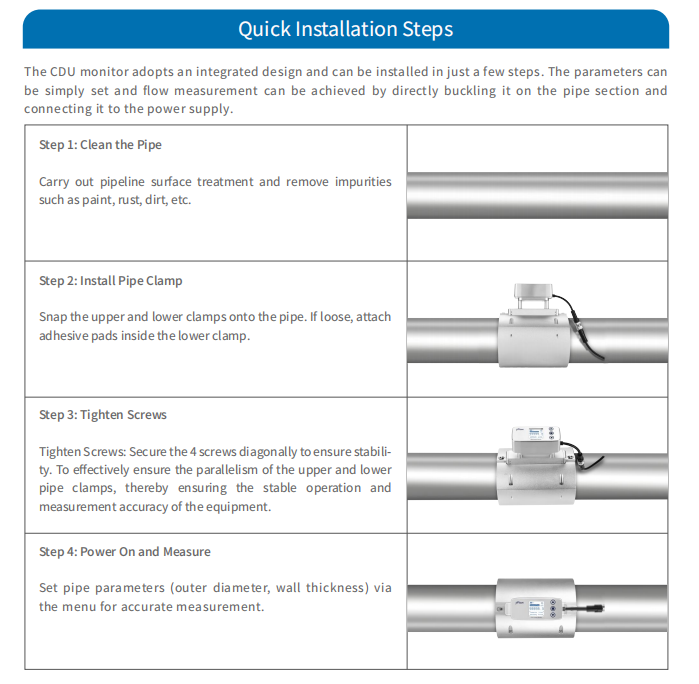

Fast installation steps

APPLICATIONS

l Energy Saving

l Carbon Audit and Management

l Liquid Cooling Data Center

l Agriculture and irrigation systems

l Water and wastewater management

l HVAC (Heating, Ventilation, and Air Conditioning) systems

l Process industries (chemical, pharmaceutical, food and beverage)

l Energy management and environmental monitoring

l Research and development

l Facilities management

l ndustrial maintenance and troubleshooting

D5 Application Case

CERTIFICATE

ABOUT SHIPPING

ABOUT US

1. Gentos Measurement & Control Co, Ltd. was established in 1993.

2. We focus on different types of ultrasonic flow meters almost 30 years.

3. We have our own factory to make exquisite appearance & optimal products.

4. We have 10 to 20 engineering employers to be working on research & development.

5. All our products are designed and manufactured by ourselves.

6. Each department works together to provide best service for our customers as well.

FAQ:

Q1: Do you have stock?

A2: Yes, we have safety inventory. We have a complete production line to meet bulk orders

Q2: How to ensure the quality of your products, will the finished product be inspected?

A2: Yes, every step of production and finished product must be strictly checked by QC before shipment.

Q3: How long is your delivery time?

A3: Lead time about 1-3 days after payment (you can get it in 5-7 days to your door).

Q4: Can you give us a discount?

A4: We can of course talk to specific numbers, but let’s make sure we’re on the same page about this solution being a good fit for your needs.

Q5: Are you a FACTORY or TRADING COMPANY?

A5: Yes,we are a manufacturer with designing, manufacturing, marketing and expor